ʻO nā Pepa PVC ʻoʻoleʻa / ʻoluʻolu / hoʻohālike i ka papa marble Extrusion Line

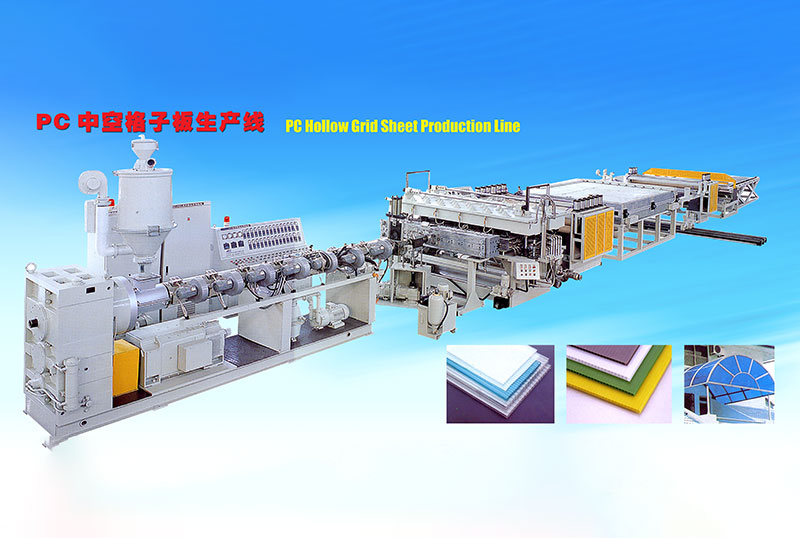

i hoʻolālā ʻia ka laina extrusion PVC Rigid i hoʻohana i ka mixer, conical twin screw extruder, T make poʻo, ʻekolu mau kalena a me nā ʻāpana o lalo, e komo pū ana me ka hoʻoluʻu ʻana a me ka ʻokiʻoki ʻana i nā kihi, ʻāpana hoʻonaninani kiʻi ʻoniʻoni, ʻāpana corona ke koho, huki ʻia ka mīkini a me ka transverse cutter. a me ka lawe ʻana i ka papa ʻaina.

ʻO ka extruded rigid PVC opaque sheets he maʻalahi ke hana, kiʻekiʻe kiʻekiʻe, nā waihoʻoluʻu like ʻole, pale ahi, kiʻekiʻe kiʻekiʻe, haʻahaʻa kumu kūʻai, hoʻohana ʻia i nā ʻano ʻano ʻano like ʻole, e like me ka panel sandwich i ke kahua kūkulu, nā ʻāpana lihi a me ka ʻili, ka paʻi maʻamau kiʻekiʻe, thermoforming packing, hoʻolaha, hoʻonaninani kūloko etc.

ʻO ka pepa ʻoluʻolu ʻo PVC kahi huahana ma mua o ka pale puka maʻamau.He palupalu, maʻemaʻe, insulation, palekana, palekana kaiapuni, kūpaʻa waikawa, ʻaʻohe ʻala, maʻalahi e hoʻomaʻemaʻe, a me nā mea ʻē aʻe, hiki ke hoʻohana ʻia i ke anuanu a me ka wela wela, mālama i ka ikehu, windproof, mālama i ka haʻahaʻa, anti-corruption, ahi. hōʻoia, anti static.ultraviolet radiation proof, soundproof, table pad, daylighting, Industrial damping, safety warning, pale i ka ʻili, hoʻohana ʻia kēia mau noi i loko o ka refrigeration, meaʻai, paʻi, ulana, uila, mea kani, lāʻau lapaʻau, mālama.He hopena maikaʻi ma ka insulation no ka uila, a me ke kukui ʻino.

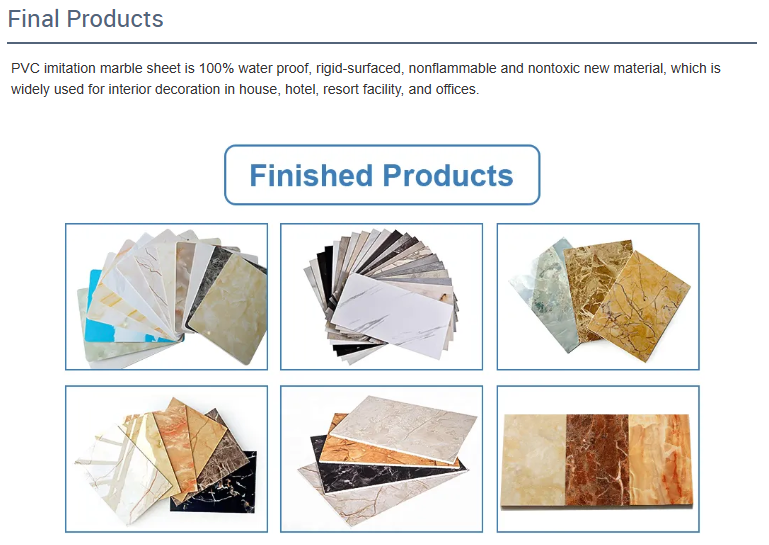

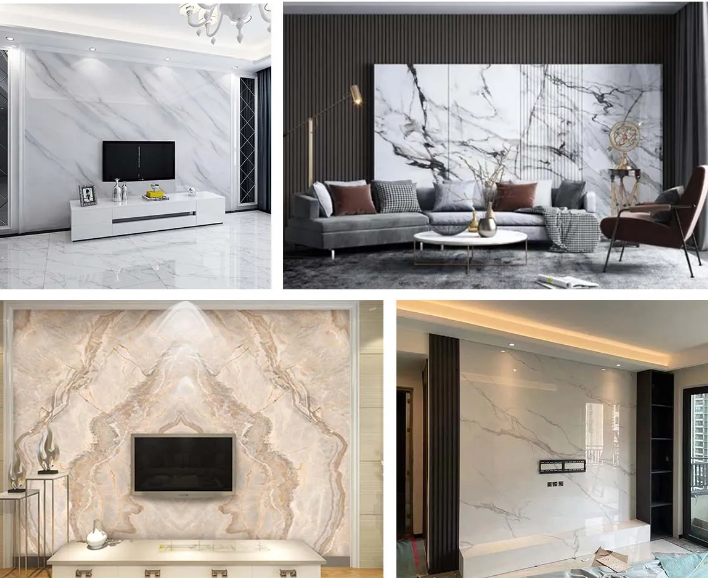

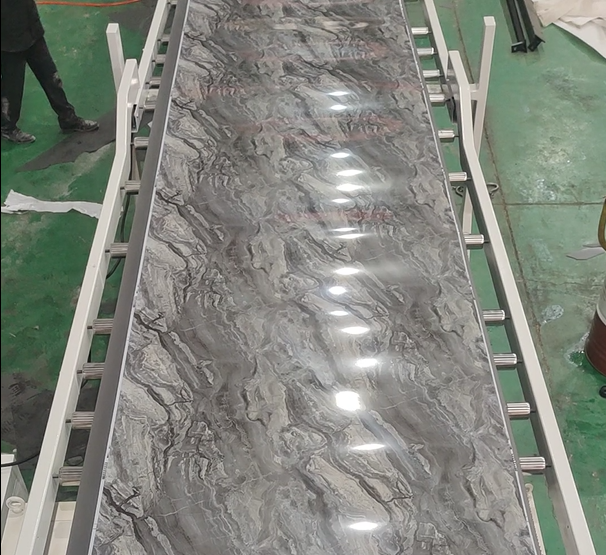

ʻO nā ʻāpana marble hoʻohālikelike, i kapa ʻia ʻo "ka pauka calcium kiʻekiʻe piha i ka PVC composite material", "stone plastic material", "high calcium material", "emitation marble material" a me nā mea ʻē aʻe. a me ka ultra-thin, super wear-resistance, high impact resistance, fire retardant, moisture and water proof, sound absorption and noise prevention, maʻalahi maʻemaʻe, hoʻohana nui ʻia ma nā wahi like ʻole, e like me ka hoʻonani i loko, nā halemai, nā kula, nā hale keʻena, nā hale hana. , nā wahi lehulehu, nā hale kūʻai kūʻai, kālepa, nā kahua pāʻani a me nā wahi ʻē aʻe.

Hoʻohālike extruder

| 'ikamu | SJSZ 65/132 | SJSZ 80/156 | SJSZ 92/188 |

| Anawaena wili (mm) | 65mm/132mm | 80mm/156mm | 92mm/188mm |

| L/D ratio | 22:1/25:1 | 22:1/25:1 | 22:1/25:1 |

| Puka (Kg/h) | 160-200 | 250-350 | 400-500 |

| Mana Hoʻokele Nui (kw) | 37 | 55 | 110 |

| Pauda Pumehana (Kw) | 4 wahi, 20Kw | 5 wahi, 38Kw | 6 wahi, 54Kw |

Nā kikoʻī

01 Conical Double Screw Extruder

* Hoʻopili ʻo Screw, barrel design a me ka hana ʻana i ka ʻenehana holomua ʻEulopa

* ʻO nā mea wili: 38CrMoAlA, mālama ʻia ka Nitriding

*Hoʻohana i nā mea uila kaulana maoli me ka maikaʻi o ka holo mau ʻana.

* ʻO ka mea hoʻoponopono wela o Omron, ABB inverter, haʻahaʻa haʻahaʻa haʻahaʻa e hoʻohana iā Schneider

* Hoʻohana ʻo Gearbox i ka torque kiʻekiʻe, haʻahaʻa haʻahaʻa, paʻa paʻa niho niho pahu pahu

02 Make Extrusion

*Ke ʻano hoʻohui o ka T-die a me ke poʻo mīkini: ʻAno Flange me ka pili bolt

*Kōkohu make: ʻAno pā lole

* Ka laula o ka papa make: 1350mm

* Ke kiʻekiʻe o ka lehelehe make: 2mm-8 mm

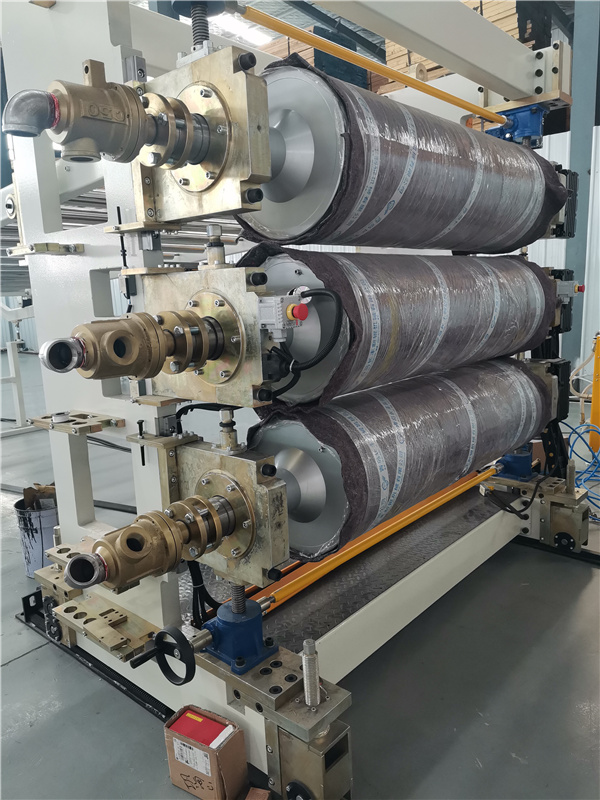

03 ʻAlena ʻekolu ʻōwili

*Kiʻekiʻe kiʻekiʻe seamless kila paipu

* ʻO ka ʻili wili me ka mālama kinai ʻana, a laila uhi ʻia ka chrome a poni ʻia

* ʻO ka paʻakikī o ka mea kumu> HRC50

*Ke ʻano o loko o ka roller: ʻano hoʻoikaika

04 Pūnaehana hoʻomalu ʻaila wela pāhāhā

*Kōkohu: ʻAno kū hoʻokahi

*Mea hoʻoheheʻe wela: ʻAila lawe wela wela kiʻekiʻe

*Mea hoʻoluʻu:Ka wai palupalu

*Pono kaohi ʻana o ka wela:±1 degere

*Pūnaehana hoʻomehana:1,Stainless steel uwila pumehana lāʻau

* Mana hoʻomehana:16KW*3=48KW

05 Paʻa moe huila hoʻoluʻu

* Nā huila hoʻoluʻu lehulehu;

*Ka hoʻomalu ʻana i ka wikiwiki e ka inverter frequency

* Hoʻopili i ka hoʻokele ʻana me ka pneumatic

*Me ka hoʻohana ʻana i ka wili lāʻau pale pale

06 Tractor huila Rubber

*Ke ala hoʻoheheʻe: ʻO ka hoʻoheheʻe ʻana

* Nui kaʻa: Φ237mm * 1500mm

*Mea o ka huila: Rubber

* Keʻano hoʻopili : Pneumatic clamping

*Ke kaʻa kaʻa kaʻa: 2KW

*Ka māmā holo: 0.4m-3.5m/min.

07 Mīkini ʻoki (me ka bracket)

*Max oki laula: 1500mm

*Max.ʻOkiʻoki lōʻihi: 2500mm

*Ka mānoanoa ʻoki ʻana: 2mm -8mm

* Ka mana kaʻa: 4KW

*Ka lōʻihi paʻa paʻa: Photoelectric sensor

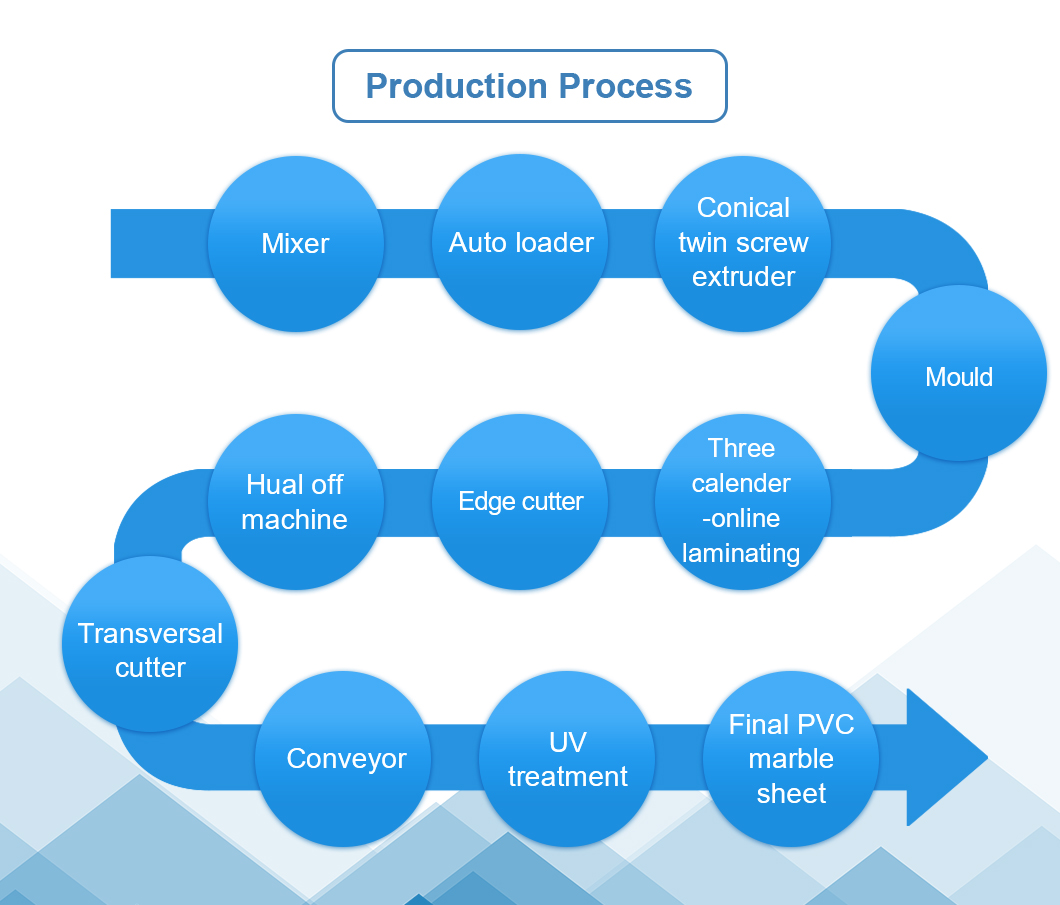

Ke Kaʻina Hana:

500/1000 Mixer → Auto loader → SJSZ80/156 conical twin screw extruder → Mould → ʻEkolu calender (online laminating) → ʻOki ʻoki → Hual off machine → Transversal cutter → Conveyor → UV mālama → Final PVC marble sheet