WPC Lako PVC Foam Kitchen Cabinet Board Make Machine

Ka papa inoa o nā mīkini a me nā pono

| ʻAʻOLE. | Ka inoa o ka mīkini | Pōmaikaʻi o ka mīkini |

| 1 | Mea hoʻoili hānai ʻakomi | 'akomi piha |

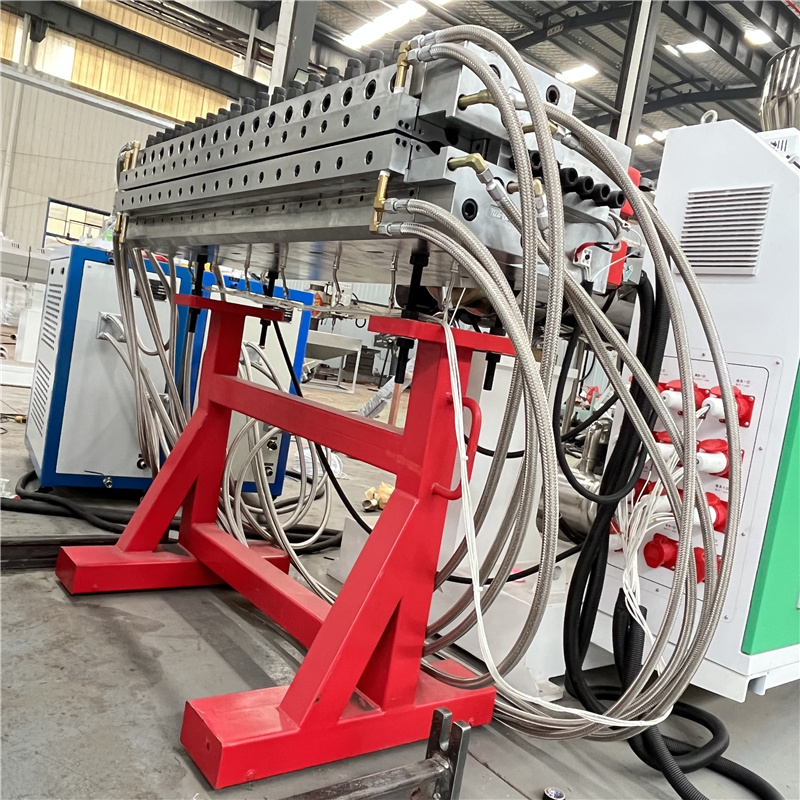

| 2 | Conical Twin Screw extruder | ʻO ke kaʻa SIEMENS i hoʻohuli ʻia, ka pahu pahu inoa kaulana a me ka hoʻonohonoho piha o ka ʻōnaehana uila SIEMENS, 30% ENERGY SAVING, STABLE RUNNING, LONG SERVICE LIFE |

| 3 | T-make | Hoʻolālā iā mākou iho me ka ʻoi aku o 15 mau makahiki hana hana |

| 4 | Kalibrator | 100mm mānoanoa aniani ili calibrator |

| 5 | Palekana Hooluu | 9 pcs wili hao kuhiliʻole |

| 6 | Wehe i ka mīkini | 8-12 mau huila ili kino |

| 7 | ʻOki ʻokiʻoki | |

| 8 | Mea hoʻopaʻa/manipulator | |

| Nā mīkini kōkua (koho) | ||

| 1 | Mea hoʻoheheʻe | No ka hana hou ʻana i ka papa kūpono ʻole |

| 2 | Mea wili/Pulverizer | No ka hana hou ʻana i ka papa kūpono ʻole |

| 3 | Mea hoʻohuihui Wela/Hoʻoluʻu Kiʻekiʻe | No ka hui ʻana i nā mea maka |

| 4 | Chiller | E hoʻolako i ka wai anuanu |

WPC Foam Plastic Furniture PVC Kitchen Cabinet Board Make Machine

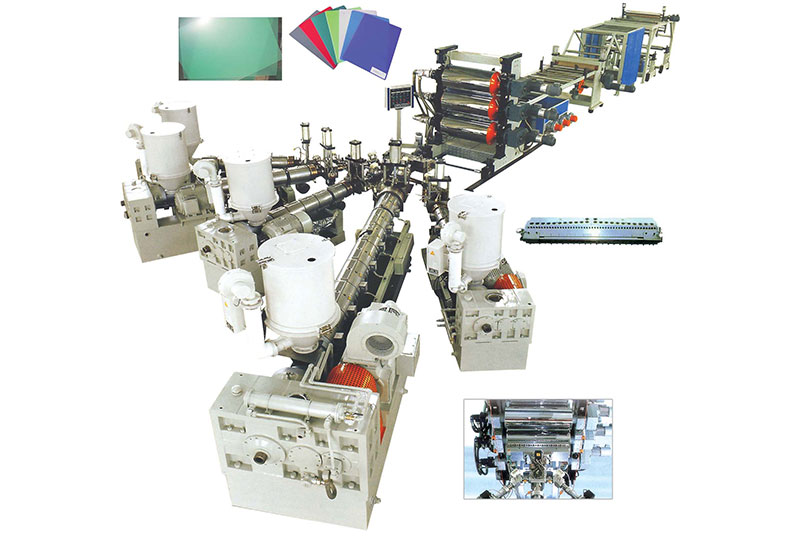

Hiki i ka mīkini papa PVC / WPC ke hana mau i ka PVC WPC foam board.This production line is composed of extruder, mold, calibrating platform, cooling frame, haul off machine, cutting machine and stacker.

Hiki i ka mea kūʻai ke hana i ka A + B + A ʻekolu papa co-extrusion foam board ma ka hoʻohui ʻana i ka extruder a me ka mea hoʻolaha . Pono ka mīkini e hoʻolako i ka chiller wai, hiki ke hoʻonui i ka hana hana.

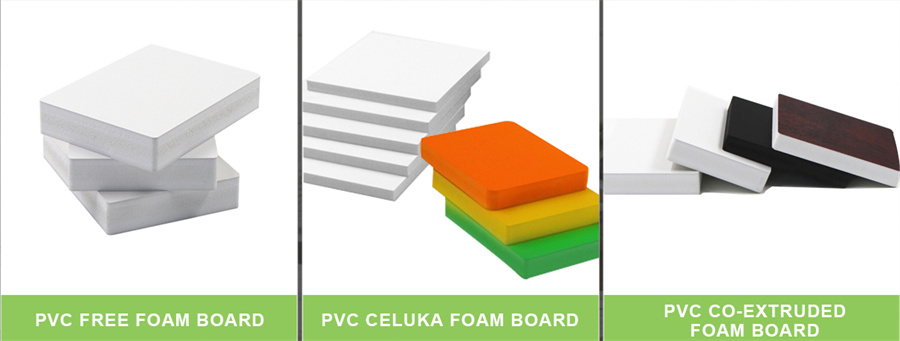

ʻO ka PVC foamed board no ka mea hou e pale ai i ka kaiapuni, i kapa ʻia ʻaʻohe papa kīnā i nā ʻāina ʻē, a ʻo ka pou pālua, ʻaʻohe leaka ʻaila, ʻaʻohe wai seepage, pale pale, kapa ʻia hoʻi ka papa blister, kumu kumu o ka papa haʻahaʻa, ka ʻili ma ka ʻōpala blister. a i ʻole ka hoʻohana ʻana i kahi kaʻina hana hoʻoheheʻe kiʻi ʻoniʻoni a PVC, ʻōmaʻomaʻo non-polluting, hiki ke hoʻololi hou ʻia, ʻo ia ka mea kūpono ambry ʻokoʻa, a ʻoi aku ka maʻalahi o ke ola o nā kānaka, ʻoi aku ka maikaʻi.ʻO ka pā pani puka i ka nui maʻamau me ka ʻole o ka ʻaoʻao, wai ʻole, ka ʻūlū, ka paʻakikī a me ka maʻalahi.